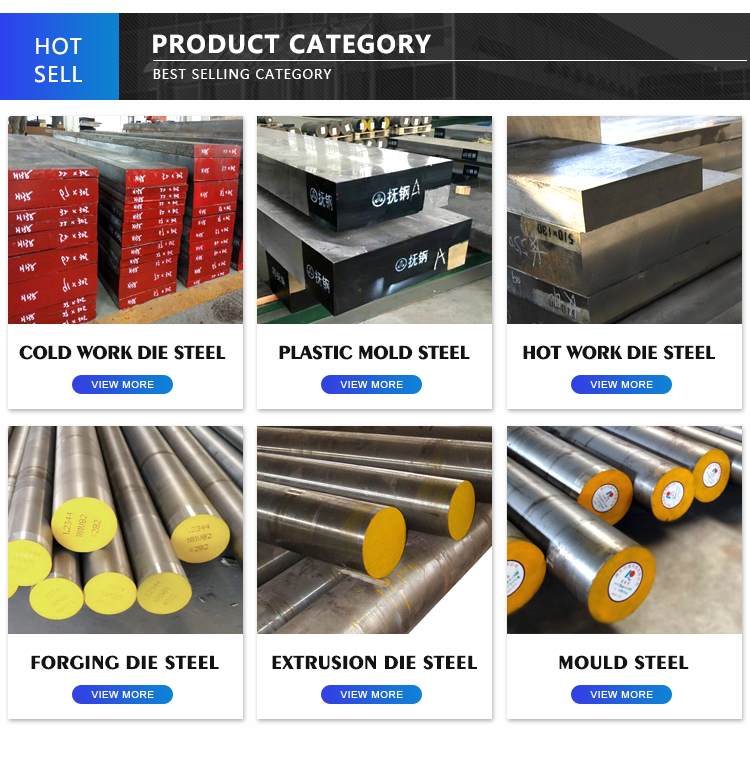

Cold work die steel

Cold work die steel refers to the die steel used to deform or form metal in a cold state. The most commonly used special cold work die steel is Crl2 steel, which has a carbon content of 1.45% to 2.30% and a chromium content of 11% to 13%. Because cold work die steel mostly works at room temperature, the plastic deformation resistance of the material is large, the working stress of the mold is large, and the working conditions are harsh. In general, the performance of this type of mold generally requires high hardness and wear resistance, sufficient strength, and appropriate toughness. Therefore, cold work die steel is usually mainly composed of high carbon to meet the needs of high hardness and high wear resistance. If in order to improve the impact resistance of the mold, when the toughness needs to be increased, medium carbon steel can be selected, and hot work die steel can be used instead. When adding alloying elements to cold work die steel, it is mainly to improve hardenability and wear resistance. For molds with high wear resistance requirements, carbide-forming elements, such as Cr, Mo, W, V, and other elements are often added. of multi-alloy steel. Considering the category of steel, cold work die steel is mostly hypereutectoid steel and ledeburite steel, generally belonging to the category of tool steel.

The performance of cold work die steel

High wear resistance

When cold work die steel is working, there are many frictions between the surface and the blank. In this case, the die must still maintain a low surface roughness value and a high dimensional accuracy to prevent early failure. Since the hardness and structure of the die material are important factors affecting the wear resistance of the die, in order to improve the wear resistance of the cold work die steel, the hardness of the die is usually required to be 30% to 50% higher than the hardness of the workpiece, and the structure of the material is tempered. Martensite or lower bainite with uniformly distributed, fine granular carbides. To achieve this purpose, the mass fraction of carbon in steel is generally above 0.60%.

High strength and toughness

The strength of the mold refers to the ability of the mold parts to resist deformation and fracture during the working process. The strength index is an important basis for cold work die steel design and material selection, including tensile yield point, compression yield point, etc. The yield point is an index to measure the plastic deformation resistance of mold parts, and it is also the most commonly used strength index. In order to obtain high strength, in the process of mold manufacturing, the toughness of the mold material should be determined according to the working conditions of the mold. For molds with strong impact loads, such as punches of cold work die steel, cold heading molds, etc. Larger loads require high toughness. For cold work die steel under general working conditions, it is usually subjected to multiple impact loads with small energy. The failure mode of the die is fatigue fracture, so the die does not need to have an excessively high impact toughness value.

Strong anti-seize

The bite resistance is actually the resistance to the occurrence of “cold welding”. Usually, under the condition of dry friction, the tested die steel sample and the material with an occlusal tendency (such as austenitic steel) are subjected to constant-speed dual friction motion, and the load is gradually increased at a certain speed, and the torque is also corresponding. increase. When the load increases to a certain critical value, the torque increases suddenly and sharply, which means occlusion occurs, and this load is called “occlusion critical load”. The higher the critical load, the stronger the occlusal resistance.

Heat softening ability

The softening ability of heat reflects the effect of temperature rise on the hardness, deformation resistance, and wear resistance of cold work die steel under load. The main indicators to characterize the softening resistance of cold work die steel are softening temperature (℃) and secondary hardening hardness (HRC).

Excellent cold work die steel factory

The above information introduces the basic information of cold work die steel and The performance of cold work die steel. If you know more about cold work die steel first, you are welcome to pay attention to an Excellent cold work die steel factory, JIANGSU TISCO INDUSTRIAL CO.,LTD, This is a steel company with more than ten years of experience in import and export. It has been trusted by customers from all walks of life for many years. We look forward to your inquiry and purchase.

Post time: Nov-08-2022