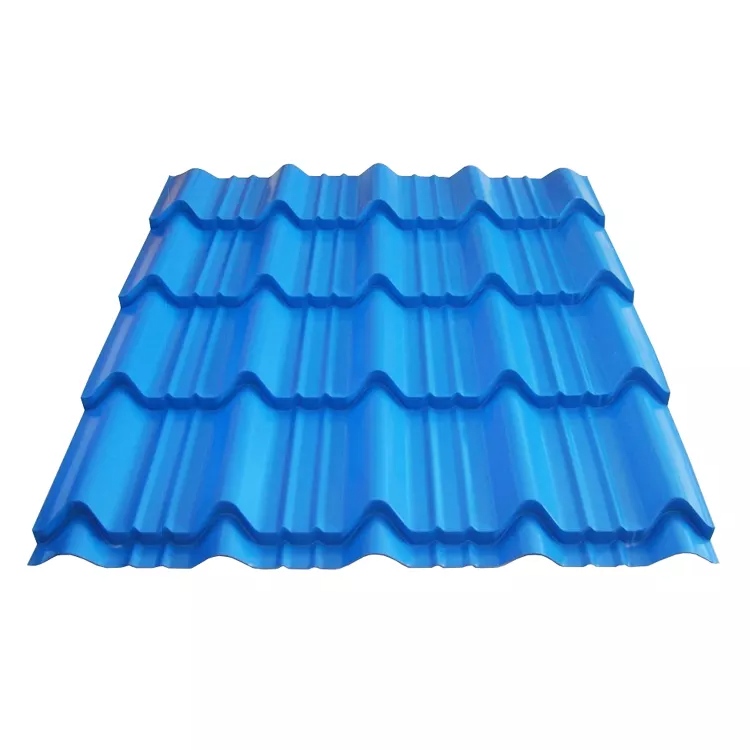

What is corrugated galvanized roof sheets

Corrugated galvanized roof sheets, also known as corrugated galvanized roof sheets or tin sheets: are cold-rolled continuous hot-dip galvanized steel sheets and strips with a thickness of 0.25-2.5 mm. The surface of the steel plate is beautiful, with block-like or leaf-like zinc crystal patterns, and the galvanized layer is firm and has excellent atmospheric corrosion resistance. At the same time, the steel plate has good welding performance and cold forming performance. Compared with electro-galvanized steel sheets, hot-dip galvanized steel sheet has a thicker galvanized layer and is mainly used for parts requiring strong corrosion resistance. Corrugated galvanized roof sheets are widely used in construction, packaging, railway vehicles, agricultural machinery manufacturing, and daily necessities. The above is the introduction to what is corrugated galvanized roof sheets.

Corrugated galvanized roof sheets treatment measures

1. Measures to control the generation of zinc slag

(1) Control the content of aluminum and iron in the zinc liquid.

(2) Control the temperature of zinc liquid. When the temperature of zinc liquid is 480~530℃, the amount of iron loss increases sharply; if the temperature is too high, it is easy to oxidize zinc and aluminum in zinc to produce zinc slag. Part of the dissolved iron is taken away by the coating, and the rest exists in the zinc pot in the form of dross, bottom dross, and free dross. Zinc dross is very easy to stick to the strip surface, affecting the surface quality of corrugated galvanized roof sheets. Generally, the temperature of the zinc pot is controlled at (460 ± 3) °C, but when the temperature is too low, the fluidity and wettability of the zinc liquid become worse, which also affects the surface quality of corrugated galvanized roof sheets.

(3) fishing for slag. In galvanizing production, the production of zinc slag is unavoidable due to the chemical properties of aluminum itself and the temperature of the zinc liquid. The scum is generally taken in the form of slag fishing. Be sure to pay attention to the scum scavenging at the outlet of the strip steel in the zinc pot. , because the scum here easily adheres to the surface of corrugated galvanized roof sheets.

2. Solutions to Thick Edge Defects

Adjust the shape of the air knife lip seam to increase the blowing pressure at the edge of the strip. More importantly, the height of the air knife should be adjusted accordingly to the speed of the production line. When the speed of the production line is low, the time for the strip to reach the air knife after leaving the zinc pot becomes longer. During the cooling process of the zinc liquid, the edge of the strip cools quickly, and the zinc liquid begins to solidify, so when it passes through the air knife, the edge of The zinc layer will be thicker. At this time, if the height of the air knife is reduced in time to shorten the cooling time of the zinc liquid, this problem can be solved. When the production line speed is high, the spraying pressure of the air knife increases, resulting in a large splash of zinc liquid, which is easy to block the air knife, so the height of the air knife should be increased in time.

3. Solutions to air knife streak defects

The operator should not increase the speed of the production line too much and pay attention to the shape of the incoming material. If the shape of the incoming material is poor, the distance between the air knives should be increased in time. Good straightness is obtained in the middle of the air knife nozzle, preventing the formation of clogging of the strip air knife. If there are air knife streaks, the air knife can be quickly opened when the weld passes through, and special tools are used for cleaning. The above is the surface defect treatment measures of corrugated galvanized roof sheets.

Excellent corrugated galvanized roof sheets factory

From the above introduction, we can understand what corrugated galvanized roof sheets and corrugated galvanized roof sheets treatment measures. Next, let me introduce our company, Jiangsu Tisco Industrial Co., Ltd. We are an excellent corrugated galvanized roof sheets factory. With 14 years of production and export experience, it is a company specializing in steel production. You are welcome to visit and buy.

Post time: Aug-23-2022