OEM/ODM Manufacturer 416 Round Bar - 316 316L 316 Ti Stainless Steel Seamless Round Pipe – Join

Short Description:

OEM/ODM Manufacturer 416 Round Bar - 316 316L 316 Ti Stainless Steel Seamless Round Pipe – Join Detail:

Chemical Component

|

GB |

ASTM |

JIS |

Chemical Component (%) |

|||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

N |

Other |

|||

|

0Cr17Ni12Mo2 |

316 |

SUS316 |

≦0.08 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

10.00-14.00 |

16.00-18.50 |

2.00-3.00 |

- |

- |

|

0Cr17Ni14Mo2 |

316L |

SUS316L |

≦0.03 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

12.00-15.00 |

16.00-18.00 |

2.00-3.00 |

|

|

|

0Cr18Ni12Mo2Ti |

316Ti S31635 |

SUS316Ti |

≦0.08 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

11.00-14.00 |

16.00-19.00 |

2.50-3.50 |

|

Ti5*C%-0.70 |

Outer Diameter: 6mm~720mm ; 1/8’’~36’’

Wall thickness: 0.89mm~60mm

Tolerance:+/-0.05~ +/-0.02

Technology:

- Drawing: Drawing the rolled blank through the die hole into a section to reduce the increase in length

- Rolling: the blank is passed through the gap of a pair of rotating rollers. Due to the compression of the rollers, the material section is reduced and the length is increased. This is a common way to produce steel tubes

- Forging: To change the blank into the desired shape and size by using the reciprocating impact force of the hammer or the pressure of the press

- Extrusion: The blank is placed in a closed extrusion container with pressure applied at one end to extrude the blank from the specified die hole to obtain different shapes and sizes

Features: 316 stainless steel pipe is a kind of hollow round steel, which is widely used in petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument and other industrial conveying pipes and mechanical structural parts.In addition, in the same bending, torsional strength, light weight, so also widely used in the manufacture of mechanical parts and engineering structures.It is also commonly used to produce all kinds of conventional weapons, barrels, shells and so on

316L stainless steel pipe has excellent mechanical properties, corrosion resistance and good weldability.In the oil and gas industry, Marine engineering, chemical industry and other industries have a wide range of applications

316Ti stainless steel is add Ti to 316 stainless steel to improve the intercrystalline corrosion resistance.It is used to resist sulfuric acid, phosphoric acid, acetic acid and acetic acid

Application:

- Oil&Gas;

- Food& Drug;

- Medical;

- Transportation;

- Construction..

|

GB |

ASTM |

JIS |

Chemical Component (%) |

|||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

N |

Other |

|||

|

0Cr17Ni12Mo2 |

316 |

SUS316 |

≦0.08 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

10.00-14.00 |

16.00-18.50 |

2.00-3.00 |

- |

- |

|

0Cr17Ni14Mo2 |

316L |

SUS316L |

≦0.03 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

12.00-15.00 |

16.00-18.00 |

2.00-3.00 |

|

|

|

0Cr18Ni12Mo2Ti |

316Ti S31635 |

SUS316Ti |

≦0.08 |

≦1.00 |

≦2.00 |

≦0.035 |

≦0.030 |

11.00-14.00 |

16.00-19.00 |

2.50-3.50 |

|

Ti5*C%-0.70 |

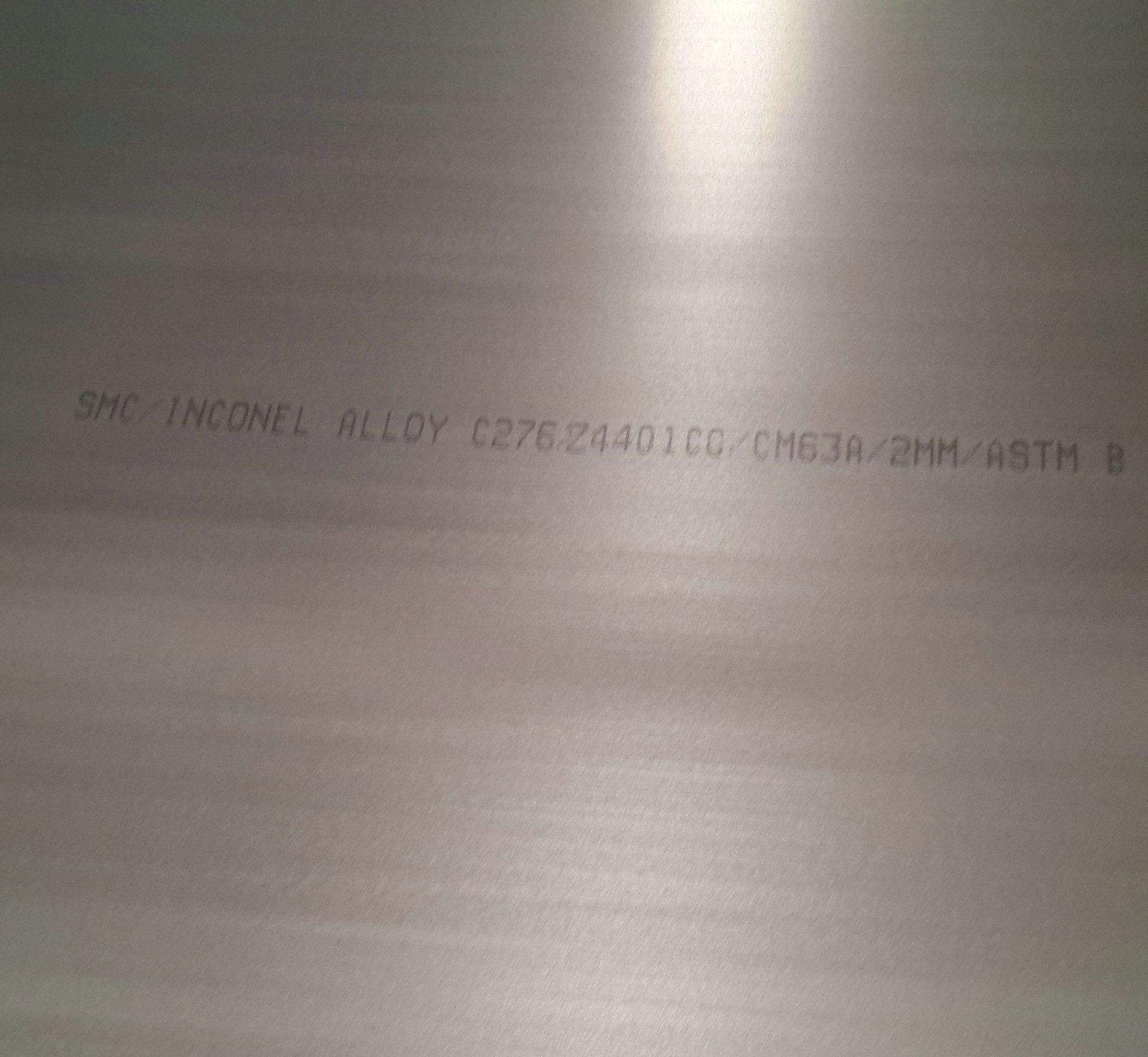

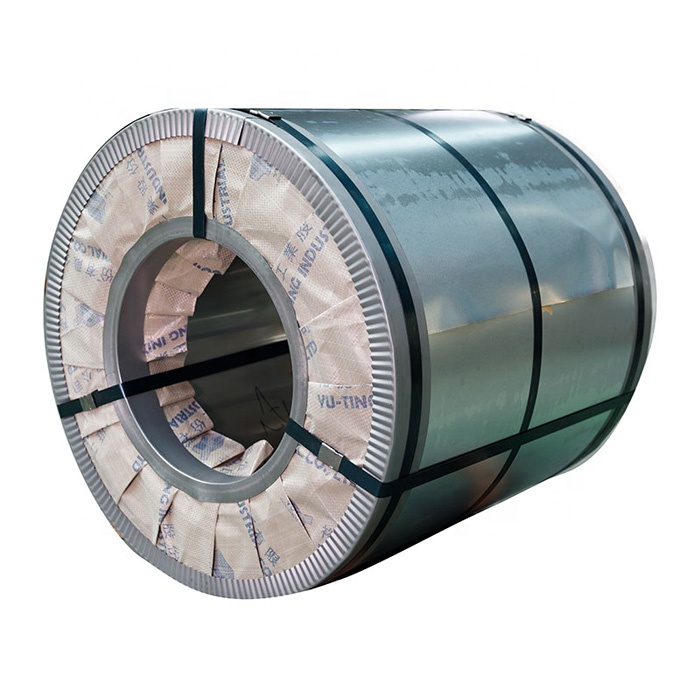

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for OEM/ODM Manufacturer 416 Round Bar - 316 316L 316 Ti Stainless Steel Seamless Round Pipe – Join, The product will supply to all over the world, such as: Guyana, Miami, Irish, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!