Aluminum sheet

Aluminum sheet refers to aluminum materials with a thickness of more than 0.2mm to less than 500mm, a width of more than 200mm, and a length of fewer than 16m called aluminum sheet or aluminum sheet, aluminum materials less than 0.2mm, and rows or strips within 200mm width. (Of course, with the advancement of large equipment, there are also many aluminum sheets with a maximum width of 600mm). An aluminum sheet refers to a rectangular sheet formed by rolling aluminum ingots, which is divided into a pure aluminum sheet, alloy aluminum sheet, thin aluminum sheet, medium-thick aluminum sheet, and patterned aluminum sheet.

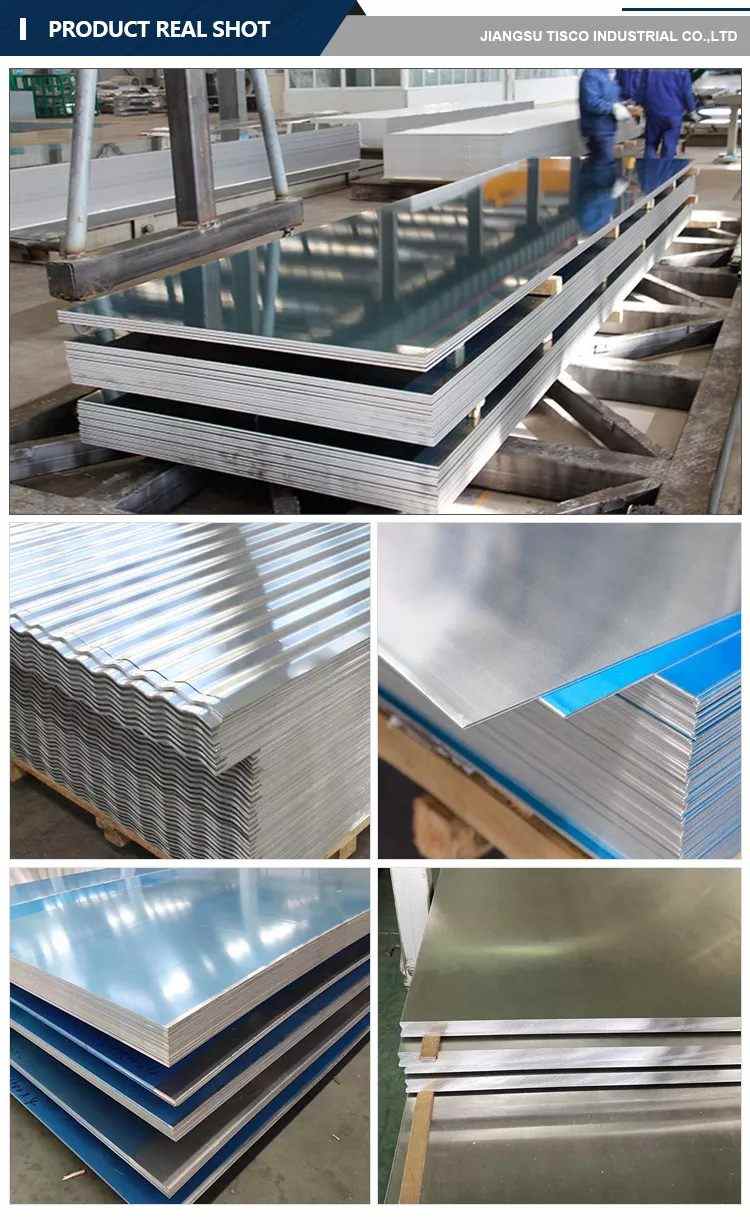

Classification of aluminum sheets

1. According to the alloy composition, it is divided into the high-purity aluminum sheet (rolled from high-purity aluminum with a content of more than 99.9), pure aluminum sheet (the composition is basically rolled from pure aluminum), alloy aluminum sheet (made of aluminum and auxiliary alloys) Composition, usually aluminum-copper, aluminum-manganese, aluminum-silicon, aluminum-magnesium, etc. series), composite aluminum sheet or welding plate (a special-purpose aluminum sheet material is obtained by a variety of material composite methods), aluminum-clad aluminum sheet (aluminum sheet The outer side is covered with thin aluminum sheet for a special purpose)

2. According to thickness, it is divided into unit mm): thin plate (aluminum sheet) 0.15-2.0, conventional plate (aluminum sheet) 2.0-6.0, medium plate (aluminum plate) 6.0-25.0, thick plate (aluminum plate) 25-200, super Thick plate 200 or more. The above is the classification of aluminum sheets.

Application of aluminum sheet

Lighting 2, solar reflector 3, architectural appearance 4, interior decoration: ceiling, wall, etc. 5, furniture, cabinets 6, elevator 7, signs, nameplates, luggage 8, car interior and exterior decoration 9. Interior decorations: such as photo frames 10, Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites, and so on. 12. Machining of mechanical parts 13. Mould manufacturing 14. Chemical/insulation pipeline coating. 15. Above the high-quality shipboard is the application of aluminum sheet.

Manufacturing process of aluminum sheet

Drawing aluminum sheet: The manufacturing process of repeatedly scraping the aluminum sheet out of the line with sandpaper. The primary process of the process is divided into three parts: de-esterification, sand mill, and water washing. In the aluminum sheet drawing process, the special film technology after anodizing can make a film layer containing the metal component on the surface of the aluminum sheet, and clearly show every fine silk trace, so that the metal matte shines fine. hair shine.

Oxidation of aluminum sheet: The aluminum sheet is formed by placing the aluminum sheet in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and performing electrolysis under specific conditions and applied current. The aluminum sheet of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface with a thickness of 5 to 20 microns, and the hard anodized film can reach 60 to 200 microns.

PS aluminum sheet (advertisement aluminum sheet, also known as printed zinc sheet, newspaper sheet): that is, an aluminum sheet with a printed pattern thickness of 025 or 03 on the back.

Mirror aluminum sheet: refers to the aluminum sheet that is processed by rolling, grinding, and other methods to make the surface of the sheet exhibit a mirror effect.

An embossed aluminum sheet can also be called an embossed aluminum sheet: it is an aluminum product that forms various patterns on the surface after calendering on the basis of an aluminum sheet. It is widely used and is mainly used in packaging, construction, curtain walls, etc. The above is the introduction of classification of aluminum sheets, application of aluminum sheet, and manufacturing process of aluminum sheet. If you want to buy high-quality aluminum sheets, you are welcome to pay attention to an excellent manufacturer of aluminum sheets, JIANGSU TISCO INDUSTRIAL CO., LTD. This is a company A factory specializing in the production of steel and aluminum materials, welcome to inquire and buy.

Post time: Sep-20-2022